Hot Bolting

MorSafe™ Online Bolt Renewal Services

Hydratight offer safe, online bolt renewal or hot bolting services on all ASME flanges. These services are performed without any damage, leakages or interruptions in daily production.

- All ASME, API, NORSOK flanges

- All sizes

- All pressure rating

- All services, subjected to a risk assessment

- Design temperature between -101ºC (-150ºF) and 250ºC (480ºF)

Why Hydratight?

Experience: Hydratight hot-bolting services are accompanied by our highly experienced team of technicians. Our tools and procedures are designed to provide engineered solutions to our customers and maintain integrity of their assets.

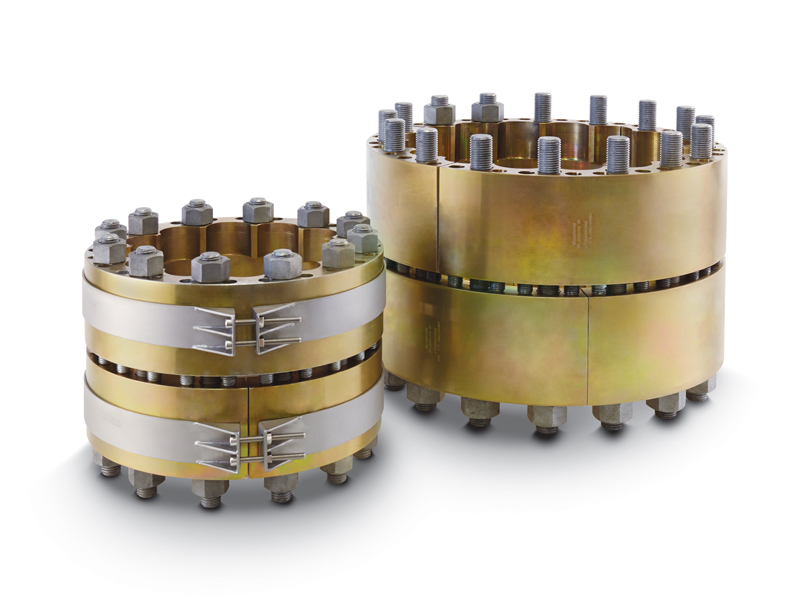

Safety: Our hot bolting solution – MorSafe™ – is designed to be simple but safe – the philosophy behind the design is to minimize the possibility of disturbing the gasket. Fitting and pre-loading Hydratight’s MorSafe™ clamp is simple; it does not require any pneumatics or hydraulics for engagement with the flange. The lightweight and compact design fits almost all flange space restrictions, and because of the robustness enables speedy bolt replacement. The patented design of our MorSafe™ hot bolt clamp design can be used on both non-hydrocarbon and hydrocarbon systems subject to satisfactory risk assessment.

Robust, yet simple design: The MorSafe™ clamp, designed in accordance with ASME, consists of segments that are bolted around the flange, using backstops to prevent the clamp pre-load from being transferred directly to the flange and gasket. Each clamp is pressure tested to 1.5 times the most stringent design operating pressure, which permits temporary installation.

MorSafe™ clamps for 4-bolted flanges are designed to enable the use of a nut splitter and approved cold bolt removal tools and techniques. MorSafe™ clamps for larger flanges with more than 4 bolts have an enclosed design with space for use of a hydraulic socket wrench, spanner and twist socket.

Safe hot bolting on old flange connections mitigates these concerns:

- Unknown remaining bolt tension after a long time in operation

- Unknown conditions of the bolts

- Unknown conditions of the gasket

- Unknown how the gasket will act under increased or decreased load

- Failure of bolts during hot bolting operation on adjacent bolt

- Unknown external loading

- Unknown how much force is needed to remove old rusted bolts

- Changes in operating parameters like flow, temperature, or pressure

- Occurrence of unpredictable situations which could cause personnel to leave workplace