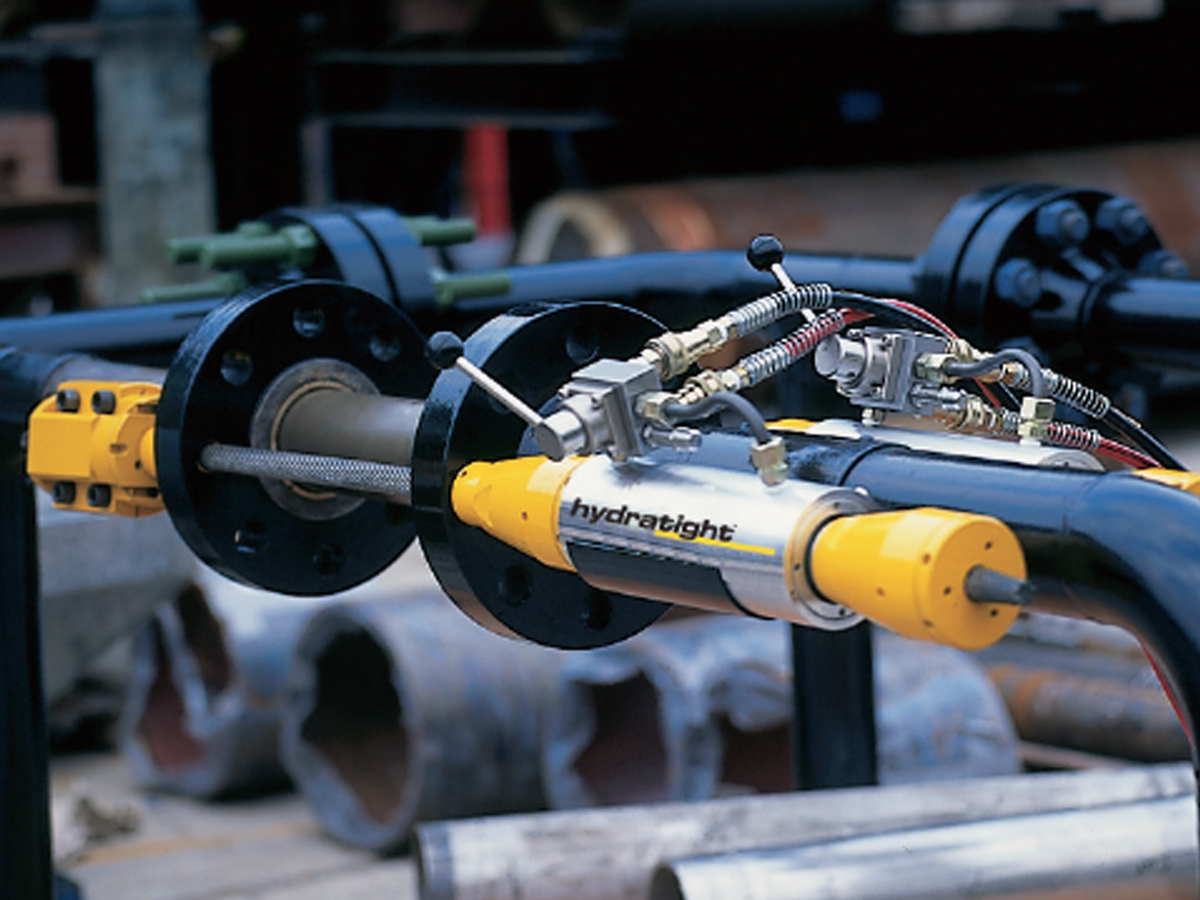

Hot Tapping

Hydratight’s hot and cold tapping service provides the solution to plant and pipeline modifications without the need to decommission, thus reducing plant downtime.

Mechanical Plugging

Mechanical PluggingHydratight’s Mechanical Line Plugging service is ideal for temporary or permanent isolation of pipe work, allowing repair or modification without the need for plant shut-down or the loss of production or process media.

Heat Treatment

The most advanced portable Heat Treatment equipment and highly skilled field technicians combine to deliver accurate and affordable on-site Resistance Heat Treatment and Induction Heat Treatment services.

Valve Testing

Hydratight’s teams of skilled engineers are able to test the response pressure of safety relief valves under normal operating conditions. This TÜV-approved computerised test system does not require any increase of operating pressure.

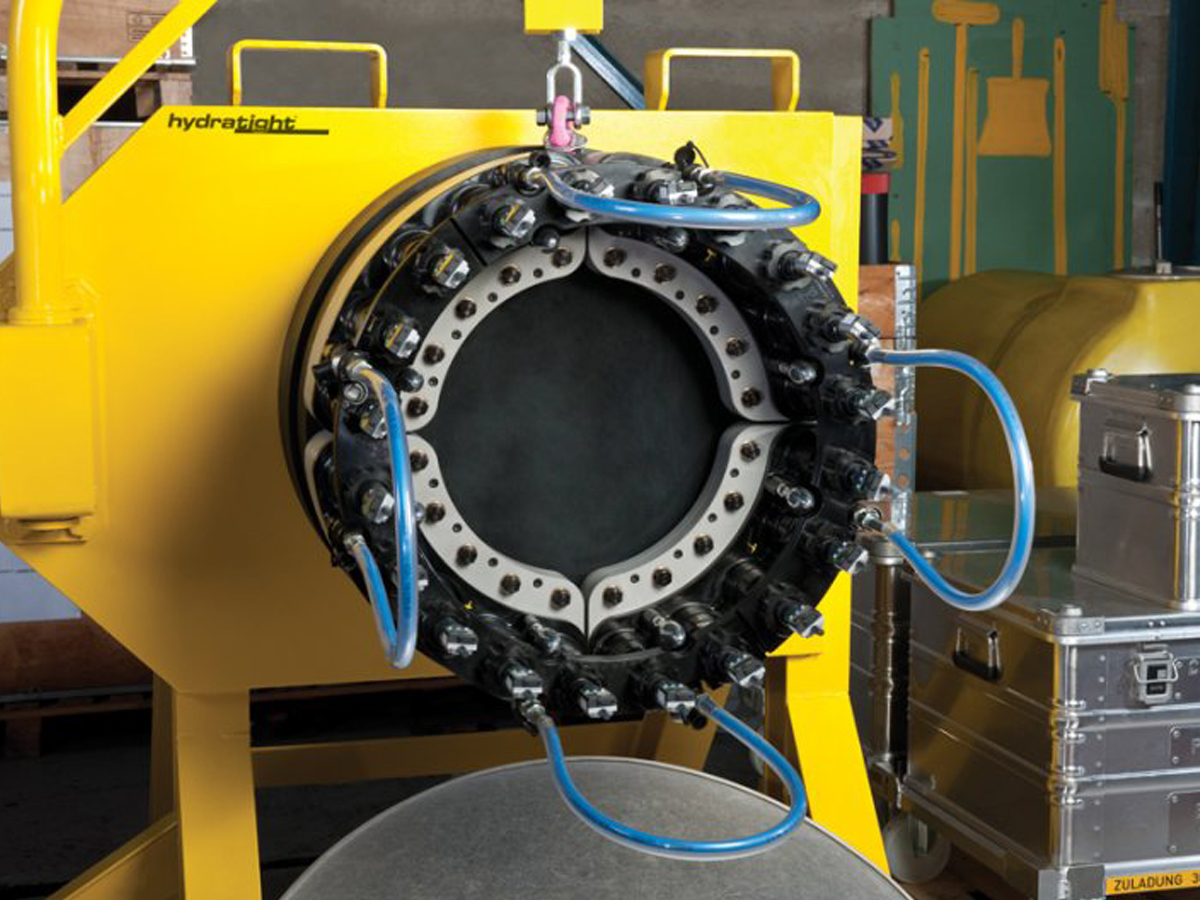

In-Line Weld Testing & Isolation

Hydratight’s qualified and professional technicians provide a safe, reliable and cost-effective means for the localised pressure testing of piping. Localised pressure testing is a means of verifying the integrity of a welded or formed joint or flange installation/weld which has been made on a piping system. Typically these are made as a repair or modification of part of a process piping system which is undertaken during plant shutdown activities.

Composite Repair

Hydratight’s Composite Repair service employs trained and competent technicians to reinforce and seal corroded or at-risk piping with Loctite composite repair solutions. This service is a fast and economical alternative to pipe replacement or welding, eliminating the need for a shutdown in most instances. Hydratight has partnered with Henkel to be a primary service provider for their Loctite composite repair solutions.

Plain End Hydrostatic Testing

Hydrostatic testing requires that a component be completely filled with a test medium such as water. Pressure is slowly applied to the test medium until the required test pressure is reached. This pressure is held for the required time at which point the component is inspected visually to locate leaks. Conventional methods of testing involves welding a cap on the pipe end and later cutting off the cap and re-beveling the pipe end, while newer & advanced methods use external or internal gripping plugs.

Pre-commissioning Services

Hydratight has added Process and Pipeline Services to our legacy Joint Integrity Assurance offering to deliver industry leading process and pipeline cleaning, testing, verification, and integrity management services. In addition, we have standardised these services to ensure the delivery of the same highest standards to our customers irrespective of their global location.

Examination for TC02 – 03 with Engineer

Examination for TC02 – 03 with Engineer , Supervision and Forman by Hydratight under contract with PTTEP International. Special thanks for PTTEPI & IRPC permission to post on FB.

Hot Bolting

Hydratight offers safe, online bolt renewal or hot bolting services on all ASME flanges. These services are performed without any damage, leakages or interruptions in daily production.

Leak Sealing

Hydratight’s history of developing innovative technologies continues with the addition of On-Line Leak Sealing (formerly known as Injectaseal), helping you to avoid production losses and unscheduled plant shutdowns. Our expert leak sealing knowledge ensures leaks are efficiently and permanently fixed.